ISO 9001 & 14001 Certified Company

Venkateshwara Industries, a partnership firm manufacturing HDPE/PP Woven Sacks & Fabric was started in the year 1969 in Karkala. It was the 7th Industry in India to manufacture HDPE/PP Woven Sacks at the time. The factory was started by constructing its own building and setting up extruder and shuttle looms financed by Syndicate bank, Karkala. The main customers at the time were M/s. Dharamsi Moorarji, Mumbai, MCF Mangalore and Syndicate Bank, Manipal. Subsequently, the Industry was upgraded by installing circular looms by phasing out existing shuttle looms in the year 1990. Late Mr. Bola Jayawanth Hegde and Late Mr. Bola Yashwanth Hegde were the founder partners who conceived, strived and developed the industry from its inception till their death in the year 2011 & 2007 respectively.

Our Founders

Bola Jayawanth Hegde

Founder

Bola Yashwanth Hegde

Co FounderFacilities

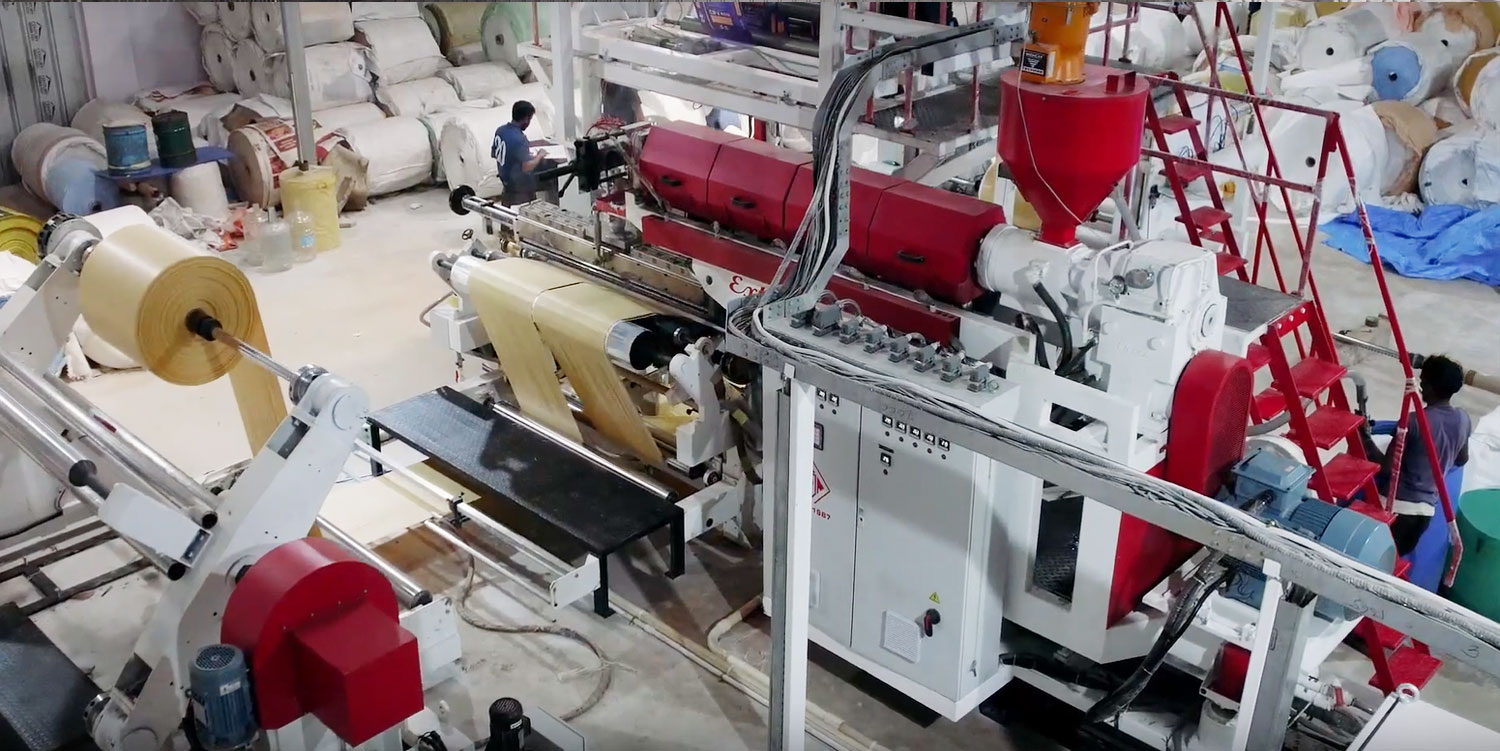

Completely Integrated and Modern Facility

Venkateshwara has a completely integrated and modern facility that is equipped with requisite experience, infrastructure and expertise to design and manufacture customized products that are tailored to meet the requirements of our valued customers. We believe in establishing close and honest long-term relationships with our clients.

- Raw Materials used for the production are sourced from the most reliable Vendors and are subject to strict quality standards before taking them further for production.

- Ensure good housekeeping , safe working practices and conservation of resources like raw material, water, electricity.

- To ensure that the products are produced as per customers requirements.

- Continuous improvement of quality management systems.

- Modern automated machines to continuously monitor production and process

Industry Capacity

Building Infrastructures & Machineries

We are committed to using the best of technology, combined with state of the art Infrastructure to offer perfection from the start to the finish, and beyond comparison

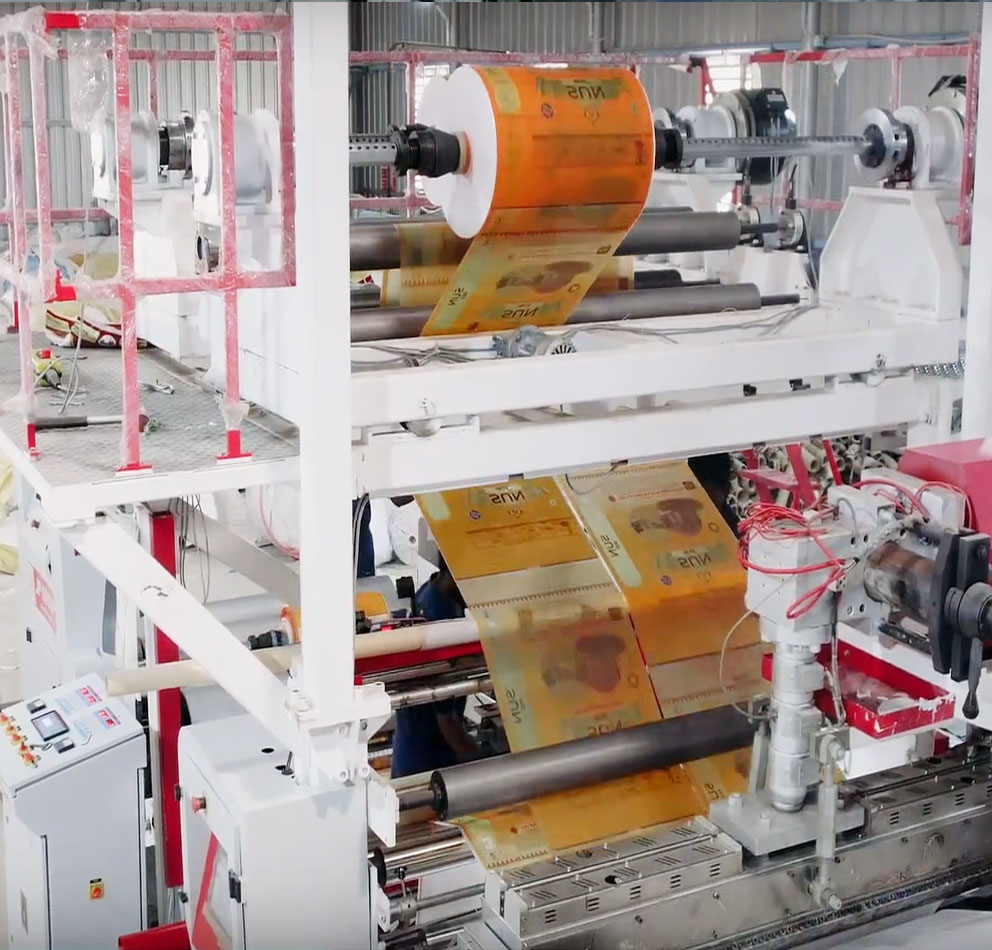

Lamination Machinery

- JP1600CR Lamination Plant with BOPP Attachment. Capacity Upto One lakh meters per shift

Stitching Machine

- #15 Arm strong stitching machines with perfect accuracy in cut length

Printing Machinery

- #2 colour, #3 colour and #4 colour Flexographic Jumbo Printing

Gusting Machine

- Float Size 12inch to 28inch 20,000meters per shift Float Size 12inch to 28inch 20,000meters

BCS Machines

- #3 high speed BCS machines with cross cutting, bottom folding, sewing and stacking capability

Factory Area

- Industrial unit with #3 Workshops having 30,000 square feet in total

Workforce

- Manpower of 25-30 people with production capacity upto 50,000 thousand bags per day